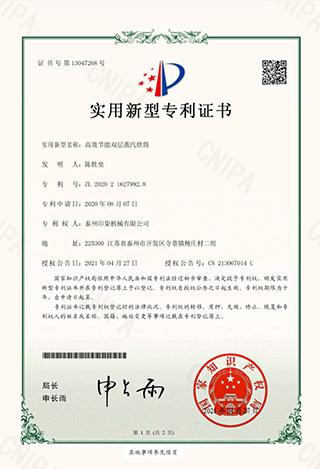

专利号:ZL 2020 2 1627992.8

公司简介

泰州印染机械有限公司成立于1978年,座落于历史文化名城江苏泰州。公司占地超过50亩,现有员工120余人。公司目前拥有配件分厂和组装分厂两个厂区。产品包括导布辊,烘筒,梅花辊,烘燥机,烧毛机,水洗机等设备。企业荣获国家高新技术企业,江苏省民营科技企业等称号。拥有包括梅花辊,烧毛机,高效振荡水洗机,双层高效节能烘筒等多项专利技术。

Company Introduction

Taizhou Printing and Dyeing Machinery Co., Ltd. was founded in 1978, located in the famous historical and cultural city Taizhou, Jiangsu.The company covers an area of more than 50 acres and has more than 120 employees. At present, the company has two parts factory and assembly factory.Products include cloth guide roller, drying drum, plum roller, drying machine, singing machine, washing machine and other equipment.The company has won the title of National High-tech Enterprise and Private Science and Technology Enterprise of Jiangsu Province.The company has a number of patented technologies including plum roller, singeing machine, high efficiency oscillating washing machine, double-stack high efficiency and energy saving drying roller, etc.

|

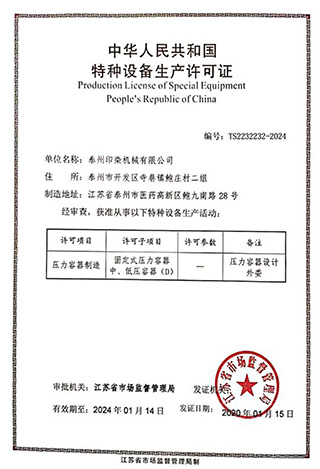

生产资质 Production qualification |

专利认证 Patent |

|

|

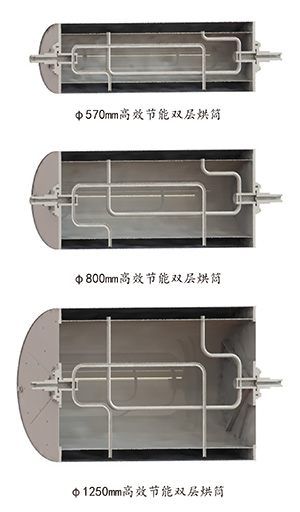

高效节能双层蒸汽烘筒结构优势:

1、高效节能双层蒸汽烘筒,缩小了烘筒内部的多余空间,在满足纺织品烘干要求的热能的基础上,能够以较快的速度将内部的冷凝水排出,减少了因为冷凝水导致的蒸汽的浪费;

2、内部空腔的体积的减少,所需提供的蒸汽压力也可以适当减少。综合改善了烘筒的能耗。

High-efficiency and energy-saving double stack steam drying roller structure advantages:

1. The high-efficiency and energy-saving double-layer steam drying roller reduces the excess space inside the drying drum. On the basis of meeting the thermal energy required for textile drying, the condensed water inside can be discharged at a faster speed, which reduces the waste of steam caused by the condensed water;

2.The volume of the internal cavity is reduced, the steam pressure required to provide can also be appropriately reduced.The energy consumption of the drying roller is improved comprehensively.

特征:

1、蒸汽压力: 设计压力:0.6Mpa; 1、蒸汽压力: 设计压力:0.6Mpa;

最大工作压力:0.58Mpa;

2、表面温度: 设计温度:153℃

工作温度:151℃

3、尺寸参数: 烘筒直径:

φ570mm、φ760mm、φ800mm、φ1250mm;

烘筒辊面长度:600-3600mm;

4、外筒体:材质为304不锈钢,厚度为2.5-3mm;

5、内筒体:材质为304不锈钢,厚度为6mm;

Characteristic:

1. Steam pressure:

Design pressure: 0.6Mpa;

Maximum working pressure: 0.58Mpa;

2. The surface temperature:

Design temperature: 153℃;

Working temperature:151℃.

3. Size parameters:

Drying roller diameter: φ570mm, φ760mm, φ800mm, φ1250mm;

Length of the surface of the drying roller: 600-3600mm;

4. Outside the cylinder:

The material is 304 stainless steel, and the thickness is 2.5-3mm;

5. Inside the cylinder:

The material is 304 stainless steel, the thickness is 6mm;

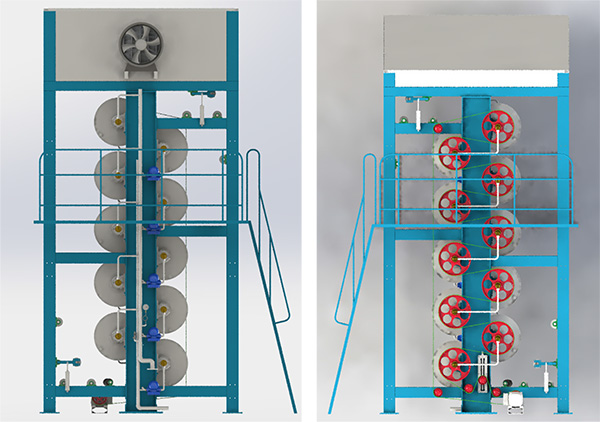

双层蒸汽烘筒烘燥机现场安装照片:

Photo of site installation of double stack steam drying roller:

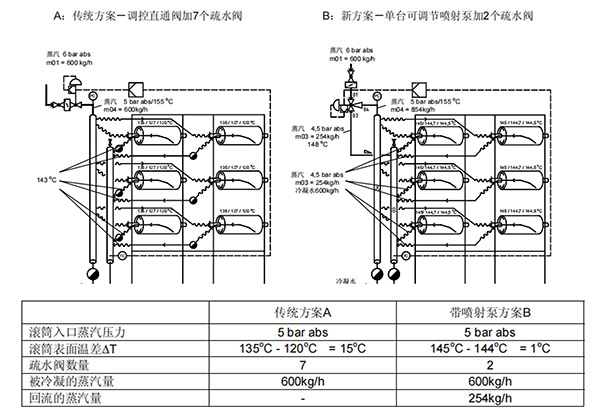

建议使用方案1:串联法

上图为10-φ800mm双层烘筒烘燥机(两支烘筒串联使用)示意图。 每两支烘筒配一只疏水器及止回阀; 蒸汽节约率如下图所示:

The figure above is a schematic diagram of the 10-φ800mm double-stack dryer (two drying rollers in series), each two drying roller is equipped with a trap and check valve; Steam saving rate is shown in the figure below:

织物类别

Fabric category |

克重

Gram weight(g/m2) |

节约蒸汽

Steam saving |

轻薄型织物

Light-weight fabric |

≤100 |

about 8% |

中薄型织物

Medium-weight fabric |

100-250 |

about 12% |

厚重织物

Thick fabric |

≥250 |

about 16% |

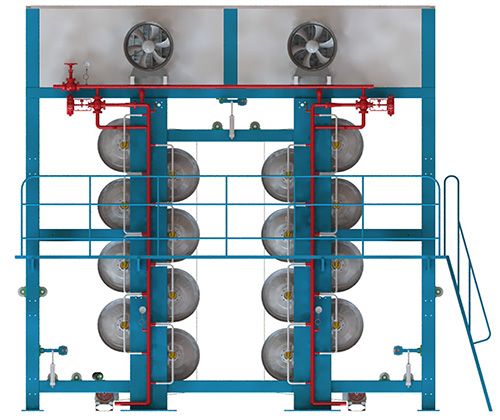

建议使用方案2:蒸汽喷射泵

上图为烘干机蒸汽喷射加热系统。 * 红色管道为蒸汽喷射泵管路示意图

Above is the steam jet heating system of the dryer. * The red pipeline is the schematic diagram of steam injection pump pipeline

蒸汽喷射加热是一种全新的加热理念,通过温控表自动设定加热温度,操作更简单更方便;喷射加热实现了乏汽回收,大大节省了蒸汽用量,降低了冷凝水排放温度;喷射加热使得烘筒表面温度更加均匀,极大改善了预缩工序和叶边疵布的产生,大大提高了烘燥效率。

Steam jet heating is a new heating concept, through the temperature control meter automatically set the heating temperature, the operation is more simple and convenient; Jet heating can realize the recovery of steam, greatly save the amount of steam, reduce the condensate discharge temperature; Jet heating makes the surface temperature of the drying cylinder more uniform, greatly improves the pre-shrinking pro cess and the generation of defective cloth at the leaf edge, and great ly improves the drying efficiency.

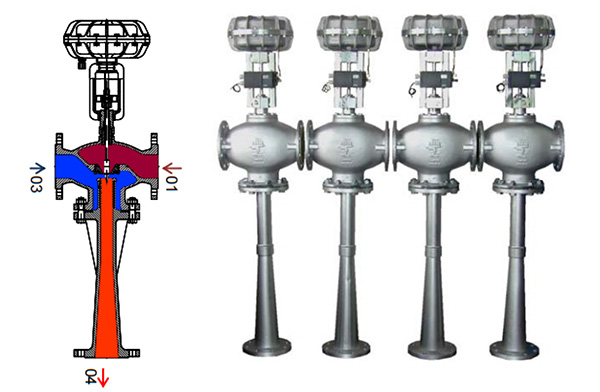

可调控蒸汽喷射泵:

可调控喷射泵主要用来促进蒸汽循环,提高低压蒸汽压力;

其原理是利用少量高(中)压蒸汽作为主动蒸汽产生的负压,将低压引射蒸汽(乏汽)抽吸入热泵泵体,并将之加压混合成一股均匀的压力较高的可用蒸汽,重新送回到系统中去(烘筒内)加以利用。

Adjustable jet pump is mainly used to promote steam circulation and improve low pressure steam pressure;

Its principle is to use a small amount of high (medium) pressure steam as the nega tive pressure generated by the active steam, the low pressure ejection steam (lack of steam) is pumped into the pump body, and the pressure is mixed into a uniform high pressure available steam, and sent back to the system (in the drying cylinder) to be used.

烘干辅助:高效液压轧车

1、高效液压轧车: 1、高效液压轧车:

适用于烘燥机前使用,大大降低蒸汽耗量;节约能源;

High efficiency hydraulic

Rolling padder:

Suitable for drying machine before use, greatly reduce steam consumption; Saving energy;

配置:

1、轧余率可达38-42%; 1、轧余率可达38-42%;

2、上主动钢辊直径φ400mm;

3、下被动橡胶辊直径φ410mm;

4、液压油泵系统1套;

5、液压油缸2台;

Configuration:

1、The roll-over rate can reach 38-42%.

2、The diameter of the upper driving steel roller is 400mm;

7、The diameter of the lower passive rubber roller is 410mm.

6、01 set of hydraulic oil pump system;

5、02 pcs hydraulic cylinders;

2、高效液压斜轧车: High efficiency hydraulic cross rolling padder:

应用及优势:

1、用于拉幅定型机前做轧液车使用,可减少能源消耗,提高生产效率,提高轧液均匀性;

2、各烘干、脱水段前做轧水车使用,以减少烘干时的能源消耗,提高烘干效率,缩短工艺流程时间;

Application and advantages:

1、It is used as a liquid rolling car before the stenter setting machine,which can reduce energy consumption,improve production effciency and improve the uniformity of rolling liquid;

2、It is used as a rolling mill before each drying and dehydration section to reduce energy consumption during drying,improve drying efficiency,and shorten process time.

主要技术特征:

1、门幅2000-3600mm;

2、轧辊直径:φ400mm;

3、加压方式:液压式加压;

4、传动形式:链轮链条传动;

5、设计最高机械车速:150m/min; |

Main technical characteris:

1、Nominal Width: 2000-3600mm.

2、Roll diameter: φ400mm;

3、Compression Mode: Hydraulic pressure.

4、Transmission Type: chain drive sprocket;

5、Designed Maximum Mechanical speed: 150m/min; |

|